Materials

The lab stocks various materials for coursework-related student purchase. These materials range from blocks of foam to wood to sheet plastics.

LUMBER PRODUCTS

| The Lab most commonly stocks Ultra-Light Density Fiberboard available in .5″, .75″ and 1.5″ thicknesses. For scale modeling and prototyping, this material works best because of its forgiving nature towards the bits. This material is easily machined, sanded and strong. The lab normally stocks Baltic Birch Plywood as well. We do not carry specialty wood products. If you look to purchase anything of the sorts- Scott Smith in the Architecture Wood Shop has specialty wood productrs available.

M.D.F.

Medium-density fibreboard (MDF) is an engineered wood product formed by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is commonly more dense than plywood; however- we stock Ultra-Light Desity Fibreboard (ULDF); which allows for quicker, safer, and more efficient machinability.

Baltic Birch Plywood

Birch ply is made from laminations of birch veneer. It is light but strong and has many other good properties. Birch ply is used to make longboards (skateboard), giving it a strong yet flexy ride. It is also used (often in very thin grades with many laminations) for making model aircraft. The lab cabinets, desktops and interior installments are made with Birch Plywood. This wood product offers strength, with a light weight- but also maintains its beauty. Suitable for any woodworking project. |

|

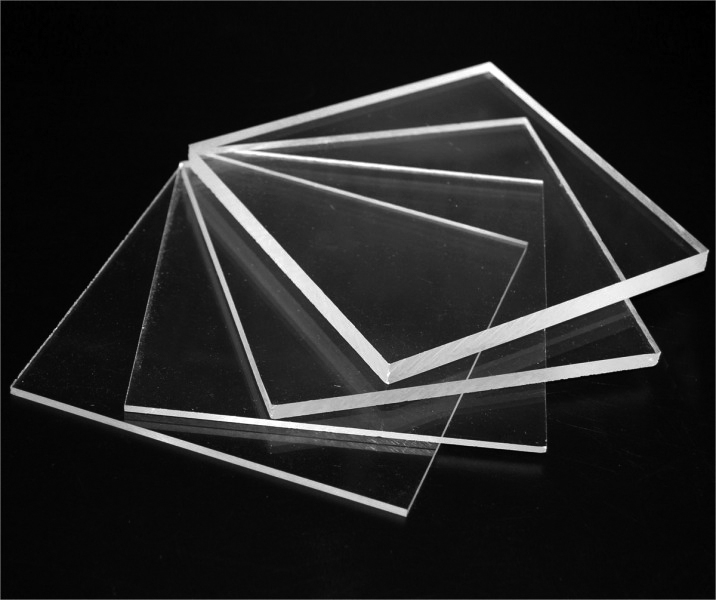

PLASTICS

| The lab stocks various plastics available for purchase. Acrylic is possibly the most commonly used and is often referred to as ‘Plexi-glass’. Acrylic comes in various tints and colors and is suitable for the laser cutter. P.E.T.G. and PolyStyrene are thin plastics used for vacuum forming. They both can be cut on the Laser Cutter, but the final product tends to be burnt, melted and unfinished. It is not recommended you use either of these for Laser Cutting Applications.

Acrylic

Acrylic is either extruded or cast. While cast acrylic offers better machinability and laser cutting, extruded acrylic is typically more cost effective. Acrylic is a plastic offered in a variety of colors and thicknesses. Typically laser cut to create a more professional finished model.

P.E.T.G.

Poly Ethylene Terephlalate Glycol (P.E.T.G) is a tranparent thermoplastic sheet. It is typically more impact resistant than acrylic, and also more cost effective. Its malleability offers deep draws for Vaccuum Forming. This product can be laser cut, but leaves you with severely burned and melted edges.

PolyStyrene

Extruded polystyrene (PS) is economical, and is used for producing plastic model assembly kits, plastic cutlery, CD “jewel” cases, smoke detector housings, license plate frames, and many other objects where a fairly rigid, economical plastic is desired. Production methods include stamping and injection molding.This material is more commonly used for Vaccuum Forming because of its malleability. It can be laser cut, but does not produce clean edges. |

|

FOAM

| The Lab stocks Extruded PolyStyrene(XPS). This foam is inexpensive, and easily machined. XPS is usually used when additional sanding is necessary. You cannot spray paint, or vacuum form these materials- they will melt. There are other more expensive options that allow for easy sanding, painting, resin coats and vacuum forming such as Polyurethane Foam. The lab however; does not have this material readily available.

XPS Foam

Extruded polystyrene foam (XPS) consists of closed cells, offers improved surface roughness and has higher stiffness and reduced thermal conductivity. Typically offered in pink, blue, or green, it has adopted the name ‘Pink Foam.’ This material is typically used for milling because of its forgiving nature towards bits and equipment as well as its machinability. You cannot spray paint, or vacuum form these materials because they will melt. There are other more expensive options that allow for easy sanding, painting, resin coats, and vacuum forming such as Polyurethane Foam. The lab however, does not have this material readily available. dFAB stocks XPS foam in 2 inch nominal thickness.

|

|