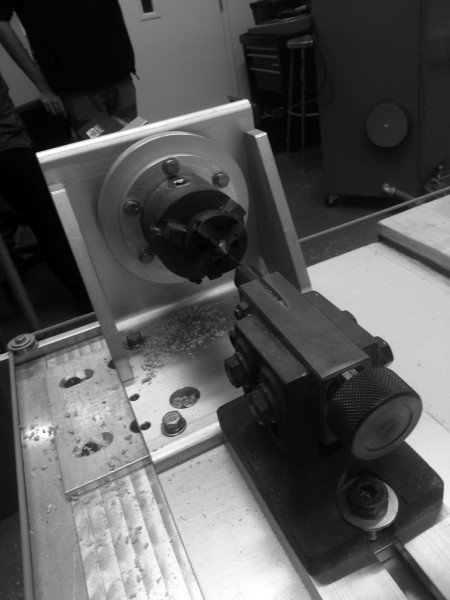

dFAB’s Facilities include (1) CNT Motion Systems 950 CNC Router, with several 3-Axis & 4-Axis capabilities. Also known as a ‘CNC Mill’, this Equipment primarily utilizes Subtractive Fabrication Methods. The CNC Equipment features a High-Speed Spindle Attachment, and C-Axis Attachment, and a Oscillating Knife Attachment. The Spindle allows an operator to select & automatically load a Milling Tool from one of the (9) available tool positions. These Milling Tools are similar to Drilling Bits, but whereas a Drilling Bit is primarily used for ‘up and down’ cutting motions; Milling Bits are uses for ‘side-to-side’ cutting motions. The Spindle automatically loads the tool and begins rotating the Milling Bit at high speeds, the CNC Router then moves the Milling Tool through previously positioned material placed on the table, and begins cutting (milling or routing) out parts and pieces. A vacuum-pump, pulling air through the porous table holds the material in place; and a Cyclone Dust Collection System takes care of the mess. This specific set-up allows the user to more efficiently process several parts from Aluminum, Plywood, MDF, Foam and various other materials. In addition, a C-Axis Attachment allows users to utilize the Equipment as a Digitally controlled Lathe. In which, the material is mounted on a rotating servo-motor, and the Milling Tools begin milling while this motor rotates the material. Lastly, the Oscillating Knife Attachment, allows users to precisely cut various thinner and flexible materials such as paper, fabrics, plastics etc. All work-flows begin with the User developing 2D and 3D geometry within a CAD Application, then transitioning that file into a CAM (Computer Aided Machining) Interface to develop paths the cutting tools are guided by. Eventually, code is generated from these files, and sent through a final application that processes and sends the code to the Equipment. These Digital Tools and Processes are used throughout multiple industries for various reasons, but are primarily utilized when manufacturing efficiency is of concern.

| Access: The 3-Axis CNC Router is available to Students within an Architecture Undergraduate or Graduate Program, and Design Undergraduates whom have attended a training session. Training sessions are available through dFAB affiliated courses. After training, Students are approved to create Equipment Reservations for the 3-Axis CNC Router. Equipment Policies and Procedures are posted here, but are also discussed during training. Specifications: Miscellaneous Milling Tools: Engraving, Compression, Lollipop Available Application Environments: RhinoCAM, MasterCAM, WinCNC, Rhinoceros, Illustrator

Important Notes: 2. Disallowed Materials: Homasote, Drywall, Steel (Ferrous Metals) 3. See Manager Regarding Milling Operations involving: Aluminum, Plastics 4. The CNC Equipment is for Research & Learning Purposes ONLY. Crafts, Gifts, ‘Buggies’, and Carnival Projects are disallowed on this Equipment. 5. Files MUST be prepared before creating Equipment Reservations. 6. Dust Collection Systems must be turned ‘ON’. Protective Eyewear is REQUIRED. Dust Masks and Ear Protection are provided and highly recommended. Closed-Toe Shoes are also recommended. 7. Fire is a primary concern when utilizing this Equipment; as a result, you are REQUIRED to stay within the CNC Room/Area while your Job is running. If a Fire should occur, STOP the Job, and notify dFAB Staff immediately. |

|

| Access: The 4-Axis CNC Lathe Attachment is available to Students within an Architecture Undergraduate or Graduate Program whom have attended training sessions. Training sessions are available through dFAB affiliated courses. After training, Students are approved to create Equipment Reservations for the CNC Router. Equipment Policies and Procedures are posted here, but are also discussed during training.Specifications: Workzone Size: <= 8″x8″x70″Available Milling Tool Diameter: .25″; .375″; .5″; .75″ (Carbide & High-Speed Steel)Available for Purchase Milling Tool Diameter: .0625″; .125″ (Carbide)Available Drilling Tool Diameter: 3mm; 5mm; 6mm; 8mm (Carbide) Miscellaneous Milling Tools: Engraving, Lollipop Available Application Environments: RhinoCAM, MasterCAM, WinCNC, Rhinoceros

Important Notes: 2. Disallowed Materials: Homasote, Drywall, Aluminum, Steel (Ferrous Metals) 3. See Admin regarding Milling Operations involving: Plastics 4. The CNC Equipment is for Research & coursework ONLY. Crafts, Gifts, ‘Buggies’, and Carnival Projects are disallowed on this Equipment. 5. Files MUST be prepared before creating Equipment Reservations. 6. Dust Collection Systems must be turned ‘ON’. Protective Eyewear is REQUIRED. Dust Masks and Ear Protection are provided and highly recommended. Closed-Toe Shoes are also recommended. 7. Fire is a primary concern when utilizing this Equipment; as a result, you are REQUIRED to stay within the CNC Room/Area while your Job is running. If a Fire should occur, STOP the Job, and notify dFAB Staff immediately. |

|

| Access: The 2-Axis CNC Oscillating Knife Attachment is available to Students within an Architecture Undergraduate or Graduate Program whom have attended training sessions. Training sessions are available through dFAB affiliated courses. After training, Students are approved to create Equipment Reservations for the CNC Router. Equipment Policies and Procedures are posted here, but are also discussed during training.Specifications: Workzone Size: <= 8’x4′Maximum Material Thickness: <= .030″Available Cutting Tools: Multiple Knife Blades (Purchase Only)Available Application Environments: RhinoCAM, MasterCAM, WinCNC, Rhinoceros, Illustrator Important Notes: 2. The CNC Equipment is for Research & Learning Purposes ONLY. Crafts, Gifts, ‘Buggies’, and Carnival Projects are disallowed on this Equipment. 3. Files MUST be prepared before creating Equipment Reservations. 4. Protective Eyewear is REQUIRED. Dust Masks and Ear Protection are provided and highly recommended. Closed-Toe Shoes are also recommended. 5. You are REQUIRED to stay within the CNC Room/Area while your Job is running. |

|

| Access: The 3-Axis CNC Router utilizes various types of Milling Tools. These Tools are utilized for various operations, techniques, and goals. dFAB, provides multiple milling tools at no cost to the User; but also stocks add’l tools that may be useful for specific operations. Milling Tools commonly break within a learning environment, and this is acceptable so long as the individual is learning. Users are not charged for tool breakage if the situation is deemed as a learning platform. However, Users are charged for Tool Breakage that occurs due to improper procedural protocol. Equipment Policies and Procedures are posted here, but are also discussed during training.Specifications: Milling Tools: Carbide, High-Speed SteelMilling Tool Types: Flat, Ball, Engraving, DrillingMilling Tool Flute Types: Up-Spiral, Down-Spiral, Compression Spiral, Vee, Straight, Brad-PointMilling Tool Diameter: .0625″; .125″; 3mm; 5mm; 6mm; .25″; 8mm; .375″; .5″; .75″, Knife Tools: Several Misc. Tools (For Purchase Only)

Important Notes: 2. Disallowed Materials: Homasote, Drywall, Aluminum, Steel (Ferrous Metals) 3. See Manager Regarding Milling Operations involving: Aluminum, Plastics 4. The CNC Equipment is for Research & Learning Purposes ONLY. Crafts, Gifts, ‘Buggies’, and Carnival Projects are disallowed on this Equipment. 5. Tool Library Information for MasterCAM and RhinoCAM may be found here. 6. Protective Eyewear is REQUIRED. 7. Tools are LOADED and UNLOADED by dFAB Staff Members ONLY. |

|